|

|

Machinery & Equipments/Sheet working mashines

|

|

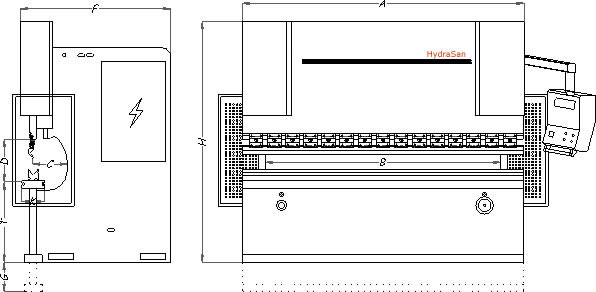

HPB870

|

|

HPB870 CNC 3 AXIS SENKRONIZE HYDRAULIC PRESS BRAKE

|

|

Print

|

| |

| Hydraulic Press Brakes |

|

Our Hydraulic Press Brakes were

designed by latest tehnology`s latest developments and in according to

customer needs with in mind working easily, security, safety and large

bending capacity.

Frames and rams are steel - welded construction

and were manufactured to be rigidity most durable on stroke workings.The

walls were manufactured by double plate boxing to increase the resistance

except under the 250 tons capacities.

|

| General Properties |

- Hydraulic cylinders are designed and manufactured from solid steel

billet and honed precisely.

- Pistons are steel forgings, hardened, chrome plated, precision ground

and micro polished for years of trouble-free service.

- Compact hydraulic block with pressure relief valves for safety.

- The torsion bar and stopper system inside cylinders enable parallel

move of top beam and accurate bend angle at both ends of the work piece.

- Pre-fill valves enable top beam to approach the work piece rapidly

and return rapidly after bending.

- Tilting of upper beam for conical bending.

- Bending is performed at slow speed according to CE norms.

- Hardened ram slide ways working with low friction and wear resistant

material and optimum lubricant material and optimum lubrication grooves.

- Pressure switch limits bending force during bending and active automatic

return of top beam to top dead centre.

- Top quality Busak Shamban seals and o-rings for long duration problem

free operation.

- High quality hydraulic fitting High pressure and silent Rexroth hydraulic

pumps.

- PLC based compact and reliable electrical system with ventilating

electrical cabinet.

|

| Accessories |

|

Standard

- Motorised cylinder stopper control system

- Digital display

- Motorised rigid backgauge(x axis)

- Longitudinal adjustment on backgazge system(Z axis and R axis)

- Backgauge positioning fingers move along linear slideways and

has deep adjustment facility of +0.05 mm tolerance for

exact parallellism

- Backgauge fingers with two gauging steps used one for short

and the other for long bending depths.

- Two adjustable fromt support

- Nuova numerical control.

- Ram stroke switches for mute point and dead centre

- T-Slotes on both sides of the table

- Foot pradl

- PLC based compact eletrical system

- Selection of metric or inc measuring system

- Side safety guards

- One piece top and bottom tools(not hardened)

Optional

- Amada Promecam crowning system.

- Front light barriers or laser systems

- Manual WILA lower block bobble system.

- Motorized WILA bobble system.

- Raer safety guards

- Additional backgauge fingers

- Top quality top and bottom tools(not hardened)

- Top tool manual quick-release clamps

- Hydraulic upper and lower crowning system.

- Pneumatic upper crowning system.

- Special upper and lower blocks.

- 500mm -600 mm extra throat depth.

- Sliding arms.

- CE certification.

|

|

|

|

Manual crowning | Power crowning

|

|

|

|

Quick release clamps | Hydraulic

tool clamping

|

|

|

|

|

|

|

| BACKGAUGE OPTIONS |

|

(A) Backgauge system with X-axis:

- Travel on ballscrew spindles

- DC-motor driven

- Two micrometric stop-fingers with height and lateral adjustment

- Range : 650 mm

- Travel speed (max): 330 mm/s

- Positioning precision: + 0.03 mm

(B) Backgauge system with X-R axes:

- Travel on ballscrew spindles

- DC-motor driven

- Two micrometric stop-fingers with height and lateral adjustment

- Range :

- X-axis : 650 mm

- R-axis : 160 mm

- Travel speed (max):

- X-axis : +0,03 mm

- R-axis : +0,03 mm

(C) Additional backgauge axes for special applications:

|

|

|

|

X1-R1-Z1 & X1-R1-Z1 axes

|

|

|

|

X-R-Z1-Z2 axes

X1-X2-R-Z1-Z2 axes

X1-X2-R1-R2-Z1-Z2 axes

|

|

|

|

|

|

| HPB |

|

25-080

|

30-120

|

30-160

|

30-200

|

30-225

|

30-300

|

40-120

|

40-160

|

40-225

|

40-260

|

40-300

|

40-400

|

60-200

|

60-300

|

60-400

|

60-500

|

600-600

|

60-800

|

Press capacity

Druckleistung

Basma kapasitesi

|

t

|

80

|

120

|

160

|

200

|

225

|

300

|

120

|

160

|

225

|

260

|

300

|

400

|

200

|

300

|

400

|

500

|

600

|

800

|

Bending length (max.)

Abkantlänge

Bükme kapasitesi

|

mm

|

2600

|

3100

|

3100

|

3100

|

3100

|

3100

|

4100

|

4100

|

4100

|

4100

|

4100

|

4100

|

6100

|

6100

|

6100

|

6100

|

6100

|

6100

|

Clearance between columns

Abstand zwischen Ständern

Duvarlar arasi

|

mm

|

2050

|

2250

|

2550

|

2550

|

2550

|

2550

|

3100

|

3100

|

3100

|

3100

|

3100

|

3100

|

4100

|

4100

|

4100

|

4100

|

4100

|

4100

|

Stroke

Hublänge (max.)

Piston

|

mm

|

140

|

160

|

180

|

200

|

200

|

250

|

160

|

180

|

200

|

250

|

300

|

300

|

200

|

250

|

300

|

300

|

300

|

350

|

Throat death

Ausladung

Bogaz derinligi

|

mm

|

300

|

300

|

300

|

300

|

300

|

400

|

300

|

350

|

350

|

400

|

400

|

500

|

500

|

500

|

500

|

500

|

500

|

500

|

Table height

Tischhöhe

Masa yüksekligi

|

mm

|

770-840

|

830-900

|

900-970

|

910-980

|

940-1010

|

890-960

|

910-980

|

940-1010

|

940-1010

|

950-1020

|

960-1030

|

1170-1240

|

1040-1110

|

900

|

900

|

900

|

900

|

900

|

Table under ground

Tischlänge unter Boden

Yeralti tabla mesafesi

|

mm

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

500

|

1300

|

1450

|

1580

|

1750

|

|

Dimention`s (HxLxW)

Abmessungen

Ebatlar

|

m

|

220x372x200

|

242x445x220

|

261x447x220

|

270x448x220

|

273x450x200

|

287x450x220

|

260x535x240

|

272x537x240

|

288x538x240

|

301x540x240

|

305x541x240

|

339x560x240

|

310x670x260

|

340x670x265

|

400x715x270

|

420x720x2850

|

430x720x290

|

450x725x310

|

Daylight opening

Lichenhöhe

Is alma kapasitesi

|

mm

|

380

|

40

|

430

|

440

|

440

|

490

|

400

|

430

|

440

|

490

|

490

|

550

|

440

|

490

|

550

|

550

|

550

|

550

|

Approach speed

Eilgang

Seri inis hizi

|

mm/s

|

80

|

80

|

80

|

100

|

100

|

80

|

80

|

80

|

80

|

100

|

80

|

80

|

80

|

100

|

80

|

80

|

80

|

70

|

Working speed

Biegegeschwindigkeit

Bükme hizi

|

mm/s

|

9

|

9

|

9

|

10

|

10

|

8

|

8

|

9

|

9

|

10

|

8

|

8

|

10

|

8

|

8

|

6,5

|

6

|

6

|

Return speed

Rücklaufgeschwindigkeit

Geri hiz

|

mm/2

|

80

|

80

|

80

|

100

|

100

|

80

|

80

|

80

|

80

|

100

|

80

|

80

|

80

|

100

|

80

|

80

|

80

|

70

|

Motor power

Motorleistung

Motor

|

kW

|

5,5

|

11

|

15

|

18,5

|

15

|

18,5

|

11

|

15

|

18,5

|

22

|

22

|

30

|

18,5

|

22

|

30

|

30

|

45

|

45

|

Weight

Gewicht ca.

Agirlik |

|

4,5

|

7,5

|

8,5

|

200

|

11

|

13,5

|

10,5

|

11,5

|

13,5

|

15

|

15,5

|

24

|

23

|

30

|

40

|

45

|

52

|

66

|

|

|

|

|

|

|

Close

|Print

|